Dallas, TX – INVEX, the cloud-based metal industry enterprise software has expanded the features specific for metal and steel bar and OCTG bar and tube service centers. INVEX enables bar and tube distributors to quickly take and ship orders with minimal screens and steps.

INVEX is the leading cloud metal enterprise software for the metal industry that is used by metal service centers and distributors. The metal software provides out-of-the-box features for metal companies that carry bar and energy-related OCTG bar and tube products. Common business cases such as band sawing, polishing, turning, boring, or outside processes such as trepanning and heat treatment can be handled quickly and out-of-the-box.

Inventory Control

Bar products can be received per piece, or received as a bundle at actual or theoretical weight. For a bundle of tube, the total footage of the bundle can also be recorded. For random length bundles, INVEX provides features to enter the length range of the bundle or itemize each length. When the material is picked for an order, the single bar/tube, or bundle can be weighed if needed or shipped at theoretical weight. Products can also be managed by Tag or Heat control. Heat control can be ideal for tube products where tagging each piece or bundle may not be possible. For tubular products, inventory can be searched by OD, ID, and/or Wall thickness.

Specifications

For quality, as material is received, the chemical and mechanical results that can be electronically imported are compared to the industry specifications (ASTM, ASME, MIL) to ensure they are met. Sales can later search stock by these specifications, and once sales orders are entered, the reserved stock must meet the customer specifications.

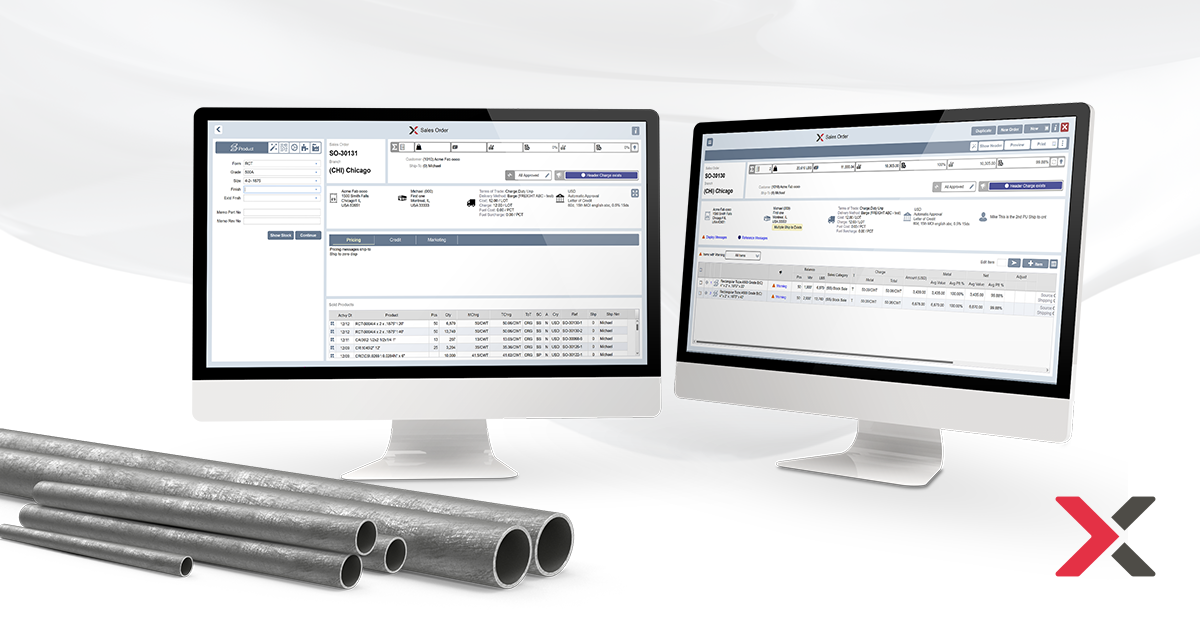

Sales

For sales, INVEX has special features when entering an order for a process such as turning that reduces the outside diameter (OD) of the bar. The quote entry dynamically handles the new OD without the need to create a new product or part number for every possible diameter. In cases such as turning and boring, the OD and ID are also dynamic in INVEX. INVEX dynamically handles the new OD/ID without the need to create a new product or part number for every possible diameter.

Production

INVEX can handle simpler cases from pick and ship, to band sawing, or more complex multi-step processing across a single or multiple warehouses including outside processing. The item route handles multiple processing steps that can be performed across warehouses (plants) or to/from outside processors. All transfer requirements are created automatically.

Introducing CIMS: The New Invera Customer Information Management System

Dallas, TX – Invera is pleased to announce the release of the new CIMS (Customer Information Management System), the next generation of our support ticket platform replacing eCIM. The new CIMS features a modern, mobile-friendly design that enhances communication, visibility, and security for both customers and business partners. Starting Friday, November 7, at 6 PM…

Triple-S Steel Implements INVEX ERP at Five Intsel West Locations

Triple-S Steel, a leading steel service center based in Houston, TX, has successfully implemented the INVEX metal enterprise software at five locations within California and Arizona. These include Intsel Steel West sites in Fontana CA, Stockton CA, and Phoenix AZ as well as Borrmann Metals sites in Riverside CA, and Burbank CA. Driving Efficiency Through…

Laura Metaal Implements INVEX, a Metal ERP Software, in the Netherlands

Maastricht, Netherlands – Laura Metaal, a steel toll processor, has implemented the INVEX metal enterprise software. INVEX is a metal-specific ERP software designed exclusively for metal service centers. The software implementation was performed by the Dutch-based INVEX partner, Prodin Solutions. Laura Metaal has implemented a full complement of INVEX software features including inventory management, sales…