Metal Service Center Software

INVEX is a cloud-based enterprise resource planning (ERP) software designed exclusively for metal service centers, featuring a specialized e-commerce platform tailored to the unique requirements of the metal industry. The INVEX metal software provides a comprehensive set of metal-specific features with a state-of-the-art cloud-based technology stack and an intuitive native web user interface.

Significantly, INVEX incorporates a metal-specific e-commerce software platform, further enhancing its functionality for the metal industry. INVEX is used by metal service centers, metal stockholders, plate processors, metal distributors, metal processors, steel toll processors, building product distributors, and steel tube mills that produce tubes from slit coils.

Metal ERP Software

INVEX offers a turn-key solution with a distinctive value proposition driven by continuous investment in cutting-edge technology and product development. From desktop to tablet and mobile applications, INVEX facilitates digital transformation for the metal industry and ensures swift implementation at steel service centers with minimal, if any, software modifications.

Metal at its core

Built specifically for the metal industry, INVEX uses native, metal-specific attributes across all screens and functions, making it the ideal choice for metal service centers everywhere.

SuiteCRM

INVEX is comes fully integrated with SuiteCRM, the world’s most popular open source CRM.

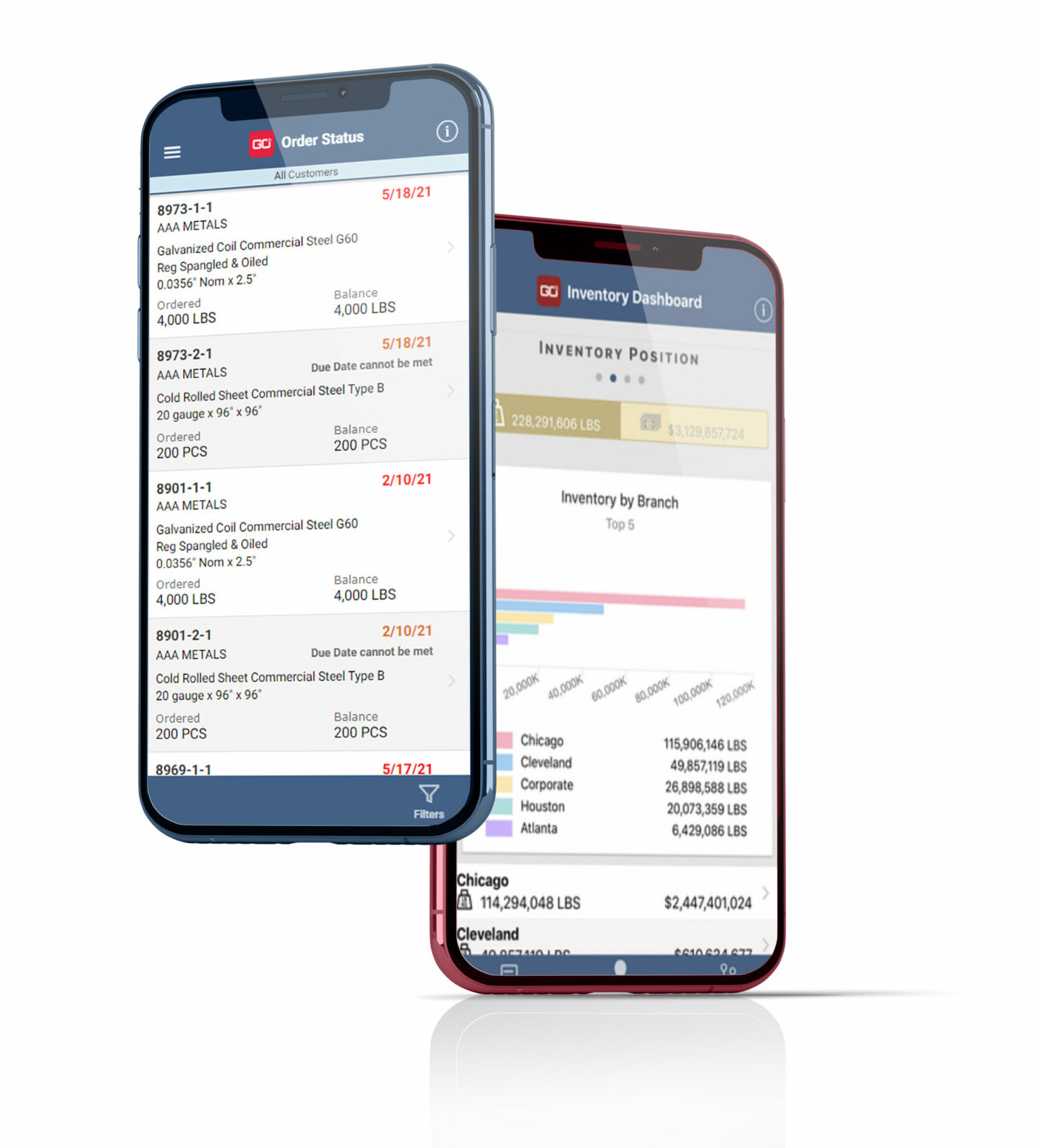

Hand-held insights

Robust mobile and tablet applications support the INVEX infrastructure by allowing management to make data-driven decisions and improve overall warehouse efficiency.

The Metal ERP + E-Commerce

Software Solution

The INVEX metal software combined with a ready-to-use E-Commerce solution provides a unique combined solution in the metal industry space. As quotes and orders are submitted by customers through the e-commerce platform, these orders are then created, fulfilled, and invoiced by the metal ERP software. Customers can also browse inventory, for items such as stainless angles or steel sheets, before adding the items to an easy-to-use cart.

Personalization & Extensions

INVEX provides a flexible and powerful toolbox to extend the use and functionality of INVEX that enables each customer to create customized data, processes and documents to meet unique business requirements. This includes creating user-defined fields (UDF) and adding these fields to the grids or screens, adding panels to existing screens, and customizing business documents, tags, and labels.

API’s to Empower Developers

The INVEX metal ERP provides a broad set of real-time data interchange methods and a suite of web standard Application Programming Interfaces (APIs) that work with external software systems to enable customers to further extend the INVEX application. Over 50 API’s are available.

Product line-based features

Each product line can have order fulfillment and process flow differences. A general metal service center needs to quote a saw-cut angle quickly and have it cut in the warehouse for same-day or next-day delivery. A flat rolled service center that produces finished slit coils in advance, to a blanket Sales Order, has its own unique requirements. Best-in-class metal ERP software

Optimized for efficiency

EDIX is an EDI (Electronic Data Interchange) ready platform that makes it faster and easier to implement EDI. EDIX helps our customers harness the power of EDI to connect to customers, outside processors, and vendors through a simple and adaptable mechanism that is fully integrated with the INVEX metal software. This approach streamlines communications between INVEX, the EDI engine, and the metal companies’ trading partners, using EDI standards such as X12, OPS, and customized transaction exchanges.

No part numbers

The inventory control and access methods used in the metal industry are unique. INVEX inventory coding is based on the metal product’s native attributes that are familiar within the industry. INVEX eliminates the use of traditional, complex, cumbersome part numbers. The industry rarely refers to inventory by a generic part number, and a wide variety of product dimensions would require hundreds of thousands of part numbers. Best-in-class metal ERP software