Monarch Steel Company, Inc., in Cleveland, Ohio, has implemented the cloud-based STRATIX metal service center software from Invera, a metal industry software specialist. The STRATIX ERP software implementation was performed with no software customizations.

Monarch Steel implemented a full complement of STRATIX features including inventory management, purchasing, sales, online production planning, coil and sheet processing functions, shop-floor production recording, job scheduling, online shipment planning, slit coil production weight recording, as well as EDI transactions.

For sales, Monarch Steel benefits from the Order Status Desktop, which shows a comprehensive status of the customer order at a single glance. Since the picking, slitting, blanking, and cut-to-length processing steps are being recorded in the warehouse, the Sales Department can see an order’s status as it goes through each process — whether scheduled, in process, or complete.

“We implemented the STRATIX software in only 4 months from the start of core team training, with no software customizations needed. The software’s functionality aligned seamlessly with our business processes and allowed for rapid implementation. The company has also realized significant benefits from the enhanced management reporting capabilities provided by the STRATIX software.”

—Ryan Amoroso, Senior Business Analyst

For production, Monarch Steel now uses an on-line production planning screen, where multiple order items can be highlighted and grouped together to create a single slitting job. The planner can then specify the arbor layout and OD breaks, as well as additional slitting specific functions such as run full or partial, slit and re-slit, and trim. This includes implementing the multiple banding and packaging features which uses bar coded pre-production slit coil ID labels that are affixed to the coils, and later used during packaging to band, scan and weigh the slit coils. The scheduling function has enabled management to better understand order volume and backlog, resulting in improved customer service.

Monarch Steel also implemented toll processing features for customer-owned metal products. These features include a streamlined Toll Order Entry function as well as specialized features for invoicing and reporting. The customer can be billed at time of shipment or production, based on consumed or produced weight, or for any charges related to scrap and storage.

The on-line Shipping Planning function provides a comprehensive, multi-layer inquiry that summarizes orders by customer, delivery route, or delivery zone for better load consolidation. The shipping department can highlight orders and create a load with a single click.

| About Monarch Steel Monarch Steel Company, Inc., founded in 1934 and headquartered in Cleveland, Ohio, is one of the country’s largest providers of hot rolled, cold rolled and galvanized steel products. The Company provides value-added processing of flat-rolled products from its service centers in Cleveland, Ohio and Decatur, Alabama, as well as ERW tubing from its Parthenon Tube, Inc. operation in La Vergne, Tennessee and its Southeast Tube, Inc. operation in Cadiz, Kentucky. |

Laura Metaal Implements INVEX, a Metal ERP Software, in the Netherlands

Maastricht, Netherlands – Laura Metaal, a steel toll processor, has implemented the INVEX metal enterprise software. INVEX is a metal-specific ERP software designed exclusively for metal service centers. The software implementation was performed by the Dutch-based INVEX partner, Prodin Solutions. Laura Metaal has implemented a full complement of INVEX software features including inventory management, sales…

Modern Metals Article: Heidtman Steel and INVEX Enterprise Software

We are excited to share the new article from Modern Metals that highlights Heidtman Steel’s journey on INVEX, the metal-specific enterprise (ERP) software. See the article below: Modern Metals – Heidtman Steel Products and INVEX Heidtman Steel, originally founded in 1954, is a flat rolled metal service center, operates eleven facilities within Indiana, Illinois, Michigan, and…

Chapel Steel – Implements INVEX, a Cloud-Based Metal Enterprise Software

Spring House, PA – Chapel Steel Corp, a steel plate distributor and processor, has implemented INVEX, the metal service center enterprise ERP software from Invera. Chapel Steel is one of the nation’s largest distributors of carbon, high strength, abrasion resistant, and specialty grades of steel plate. Chapel Steel has implemented a full complement of INVEX…

Dover Tubular Implements INVEX Metal Enterprise Software

Dover, NJ – Dover Tubular Alloys, Inc. a master distributor of stainless and aluminum tube and pipe, has implemented the INVEX metal enterprise software. INVEX is the cloud-based metal service center software from Invera that is fast to implement, and e-commerce enabled. Dover Tubular implemented a full complement of INVEX enterprise (ERP) software features, including…

Triple-S Steel – Mass Hansen and Nexcoil Implement INVEX Enterprise Software

Houston – TX: Triple-S Steel, a steel service center headquartered in Houston, TX, has implemented the INVEX metal enterprise software, at Mass Hansen Steel and Nexcoil flat-rolled metal service centers across 4 locations in California & Arizona. INVEX is the metal service center ERP software from Invera that is e-commerce-enabled. Triple-S Steel implemented, at the…

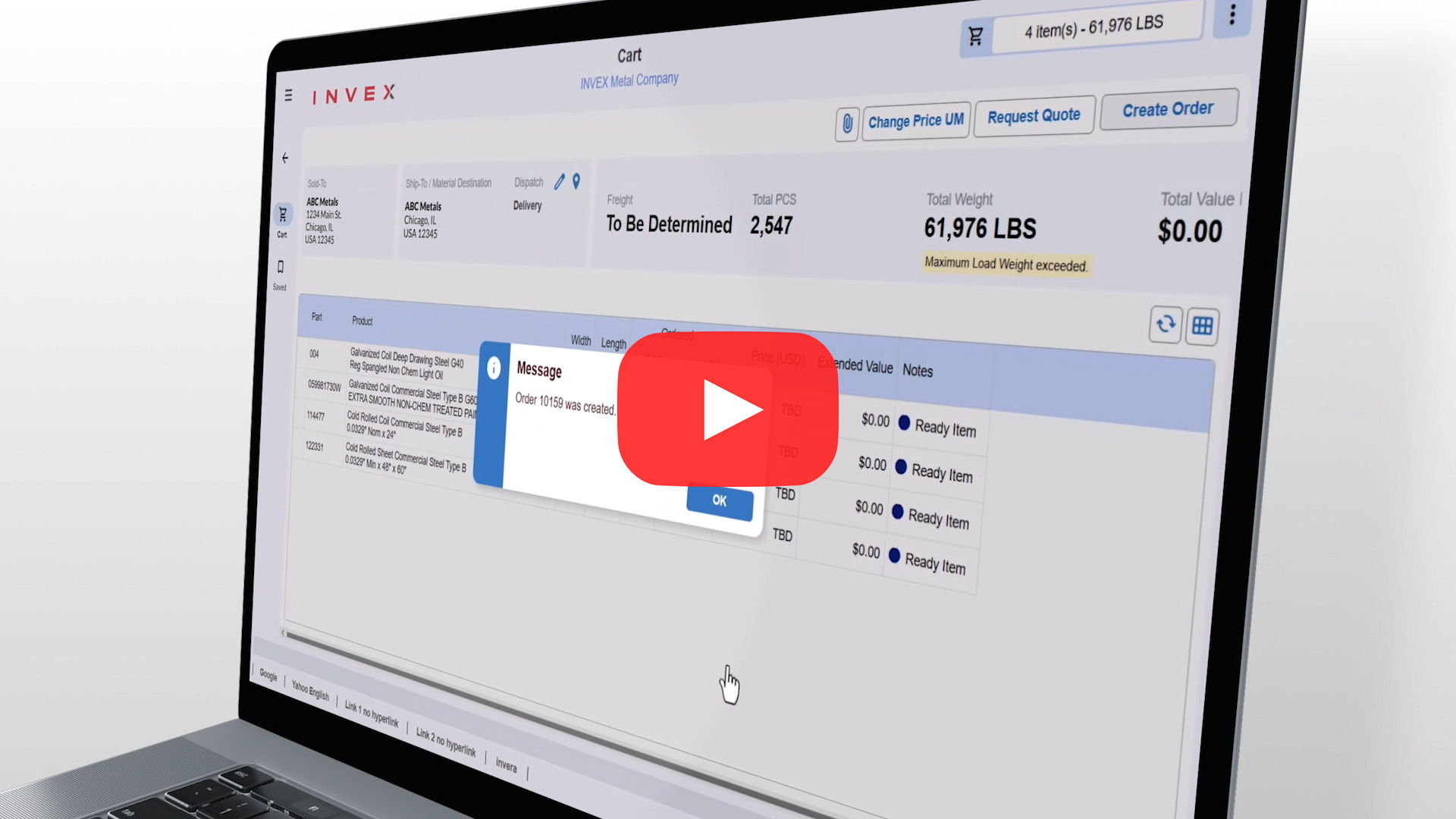

Announcing the New INVEX e-Commerce for Metal Service Centers

Dallas, TX- INVEX the metal service center enterprise software, extends into the real-time digital marketplace with the release of the new INVEX e-commerce. INVEX e-commerce seamlessly integrates with the INVEX platform, creating an end-to-end digital solution designed exclusively for the metal industry that can be implemented with minimal setup. INVEX e-commerce allows a metal service…