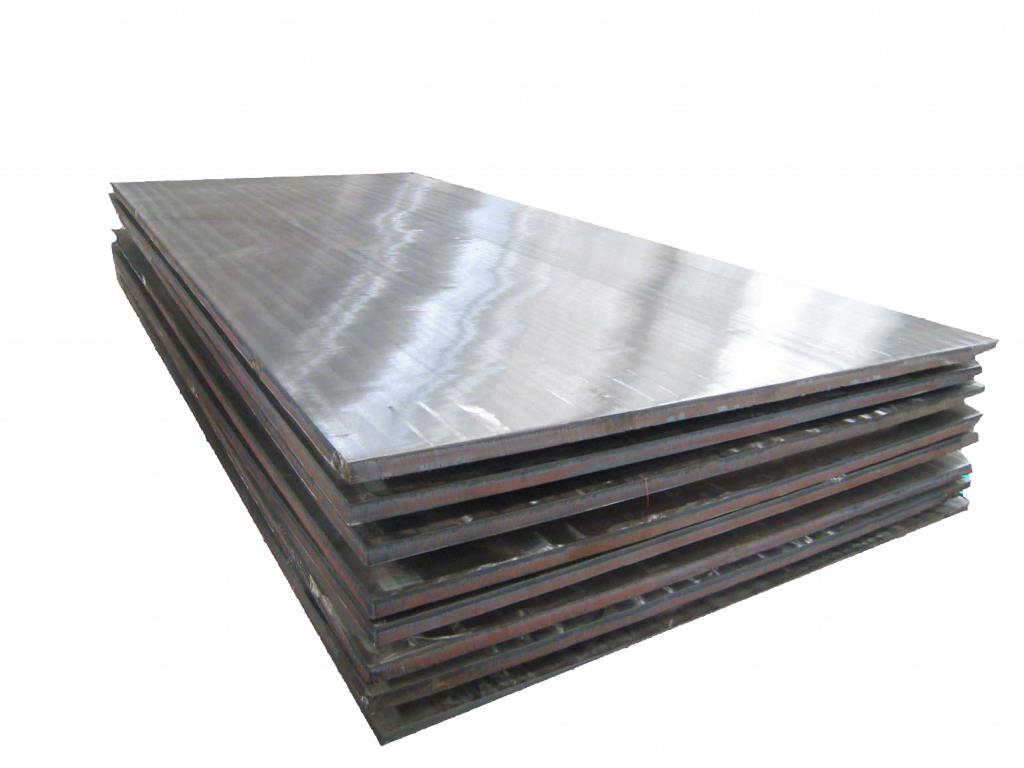

Plate

INVEX software built for service centers focused on plate processing

The INVEX cloud-based metal plate ERP software offers comprehensive functionality for metal and steel plate service centers as well as plate processors. INVEX enables these metal companies to place an order for a variety of cut shapes or irregular sketches and fulfill the order using multi-step production functions. Common plate cutting business cases, such as plasma cutting or oxy cutting, can be handled quickly and out-of-the-box.

These metal companies, also referred to as metal and steel plate stockholders, normally carry a wide range of products, which includes metal and steel plates of a variety of thicknesses and sizes.

Orders can be fulfilled using the multi-step routing function that can fulfill an order across a single or multiple warehouses.

This can include outside processing steps; all required transfers are automatically created.

Cases Handled

FAST QUOTE ENTRY

Quotes and orders can be entered quickly with a full view of stock and sales history during entry. For spot sales, orders can be entered quickly using shortcut codes or product coding attributes native to the industry.

SHAPES & IRREGULAR SKETCHES

Quotes and orders can be entered for circles, rings, triangles, and additional shapes that include irregular sketches. Irregular sketch diagrams or DXF files can be attached to the order item.

PLATE PROCESSING

For processes such as plate cutting or plasma burning, price books help calculate the cutting charge and build up the price. A capacity planning function helps verify the due date to the customer.

stacked with features

INVEX enables digital transformation for metal service centers focused on plate processing with comprehensive metal plate ERP software capabilities.