Tube Mill

INVEX software is built for tube mills and service centers focused on pipe as well as tube production

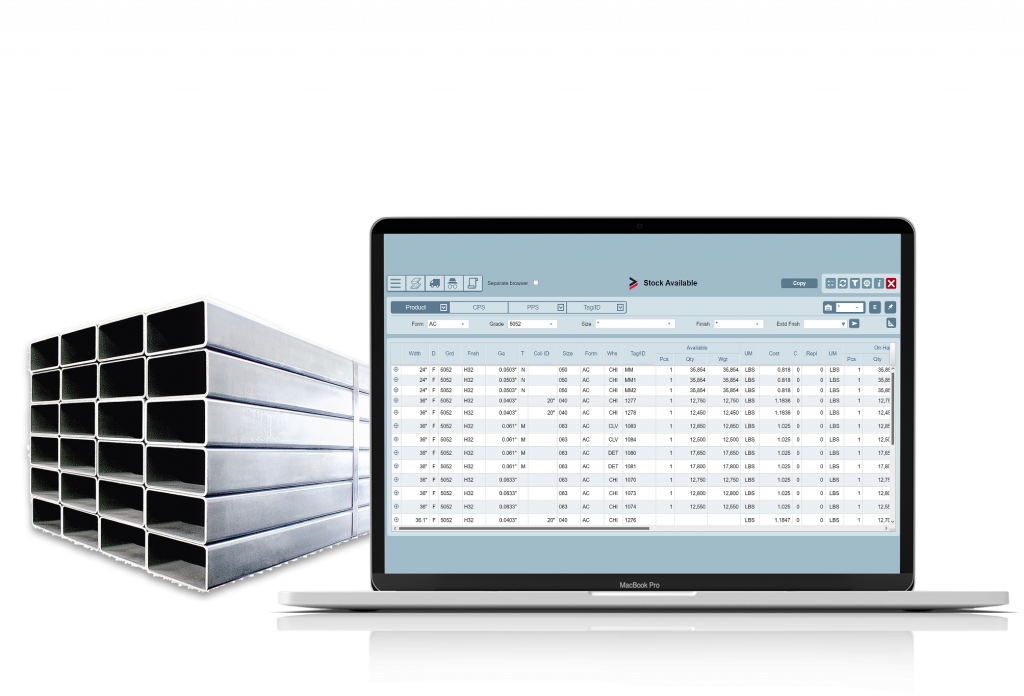

The INVEX cloud-based metal software offers comprehensive functionality for metal and steel tube mills and tube producers. INVEX enables tube mills to quickly take, produce, and ship orders with minimal screens and steps. Common business cases to produce tube from slit coil can be handled quickly and out-of-the-box.

Tube mills, which include welded pipe and ERW tube mills, produce and carry a wide range of products, which include round, square, and rectangular tube products.

Inventory can be searched by grade and shape of the tube, with additional searches by OD, ID, and wall for round tube.

In addition to viewing the heat and chemistry of the tube or bundle of tubes, the various mechanical tests that may have been taken during tube production can be viewed from the stock screen as well.

Cases Handled

TUBE PRODUCTION

INVEX includes a highly optimized set of special production recording functions that include slit charging and tube production recording. This is designed to accommodate the fast paced manufacturing process normally associated with pipe and tube mills.

TESTING

A fully integrated test entry function enables test results to be recorded for pipe/tube bundles produced from a coil-heat-batch. Accurate and valid test results are assured through validation against metal standards.

PIPE & TUBE INVENTORY

INVEX tracks the cross section and length of the tube as well as the shape, such as round, square, and rectangular. Each bundle in the inventory displays the Length, Pieces, Weight, and total footage of a bundle.

out-of-the-box solution

Tube mills can streamline their tube processing from

start to finish using the INVEX metal ERP software