INVEX

Metal ERP Software

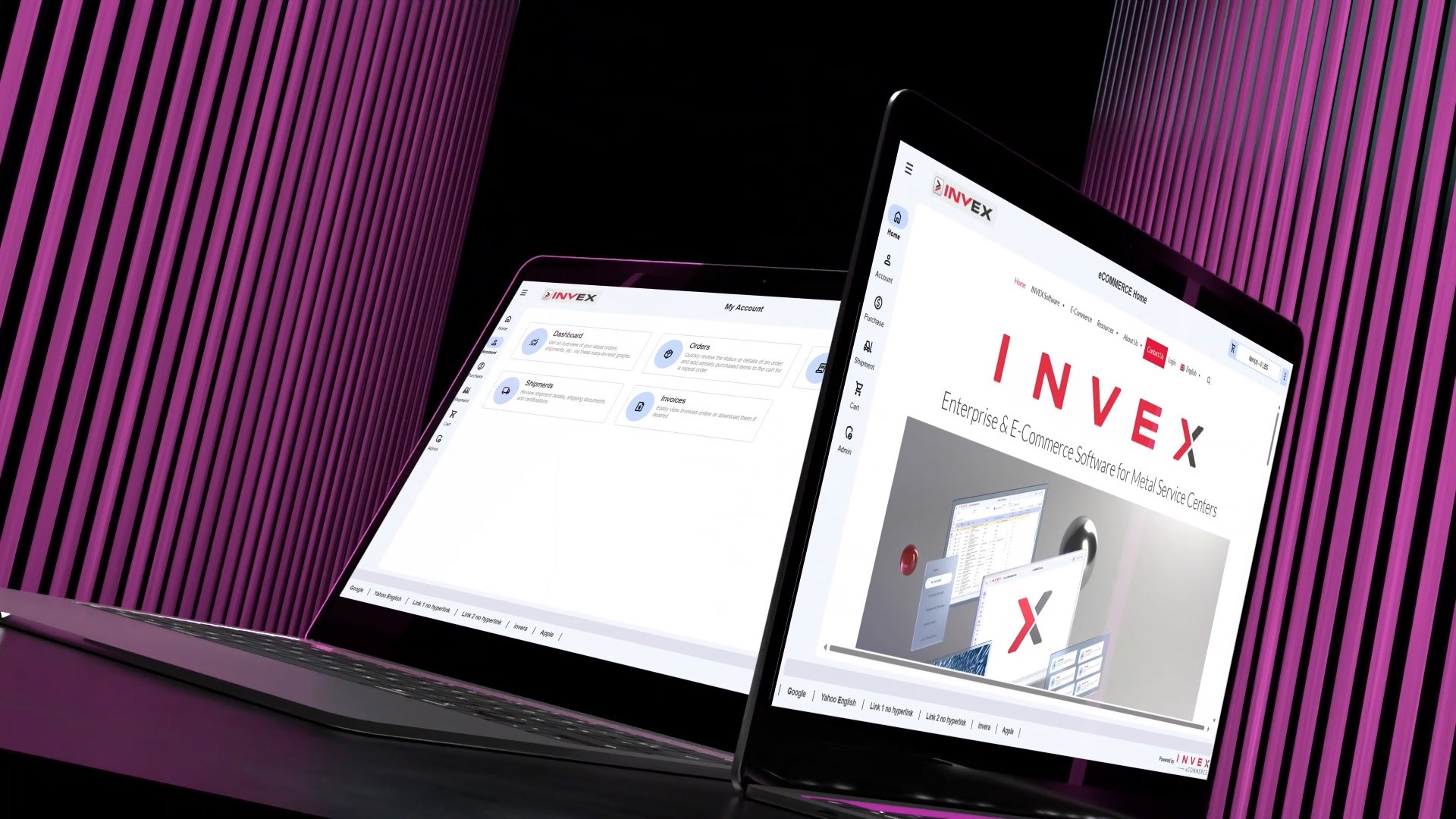

INVEX is an enterprise resource planning (ERP) software designed exclusively for metal service centers, featuring a specialized eCommerce platform tailored to the unique requirements of the metal industry. The INVEX metal software provides a comprehensive set of metal-specific features with a state-of-the-art technology stack.

INVEX is used by metal service centers, metal stockholders, steel plate processors, metal distributors, metal processors, steel toll processors, building product distributors, rolling mills, and steel tube mills that produce tubes from slit coils.

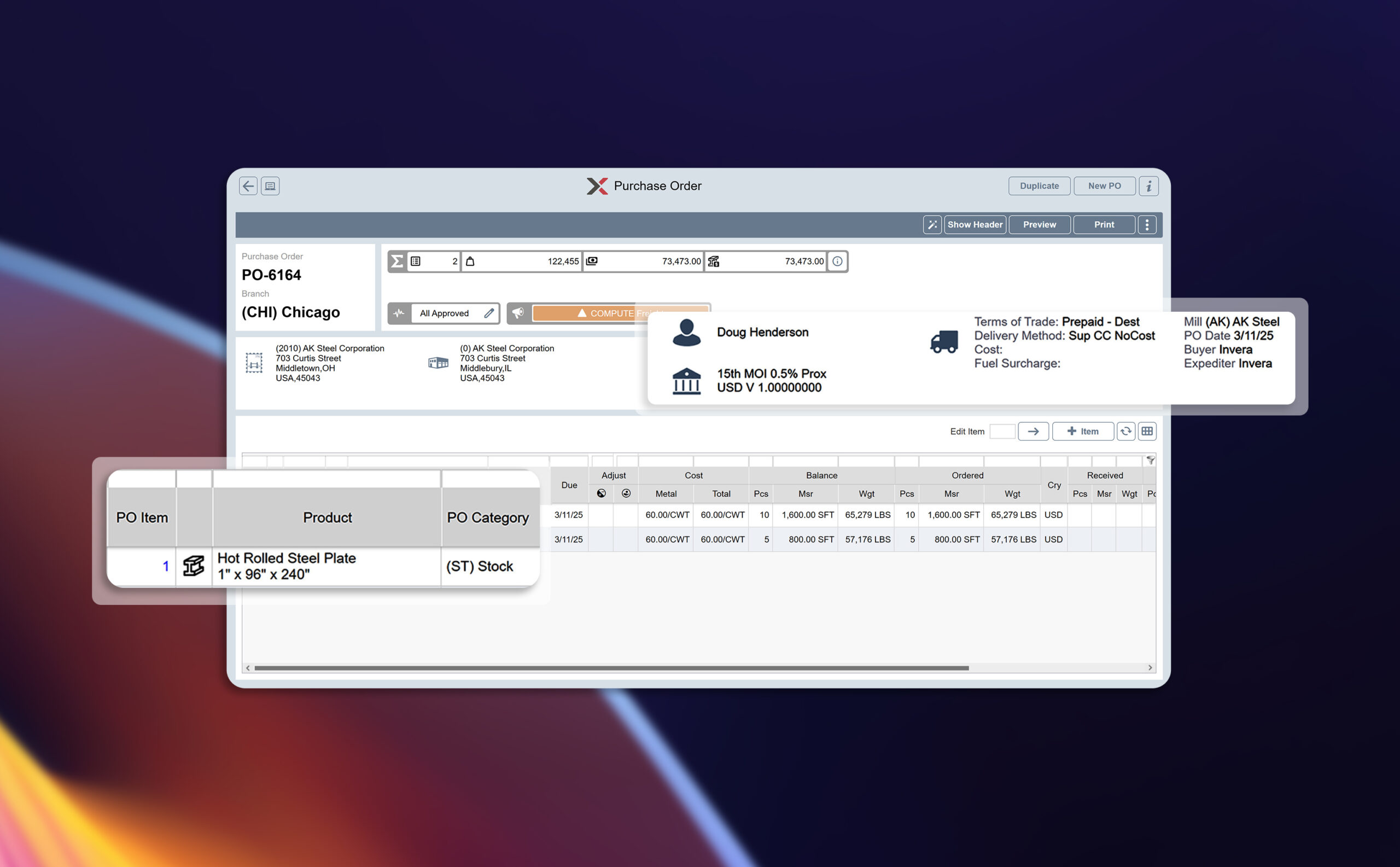

Handling metal business

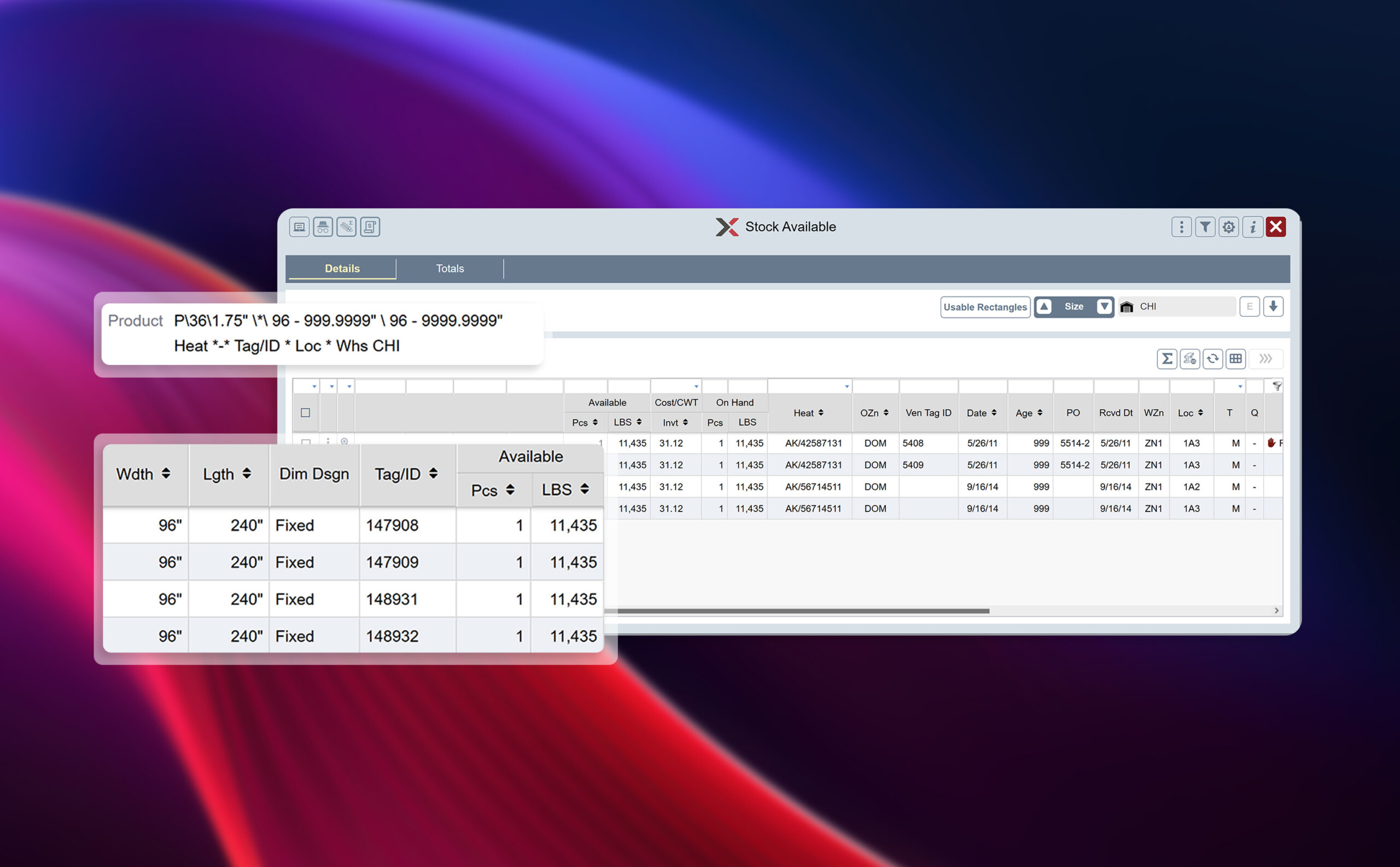

Common business cases such as stock picks, processed orders, contracts, buyouts, direct ship, outside processing, and toll processing are all built into the software and are fast to enter and fulfill.

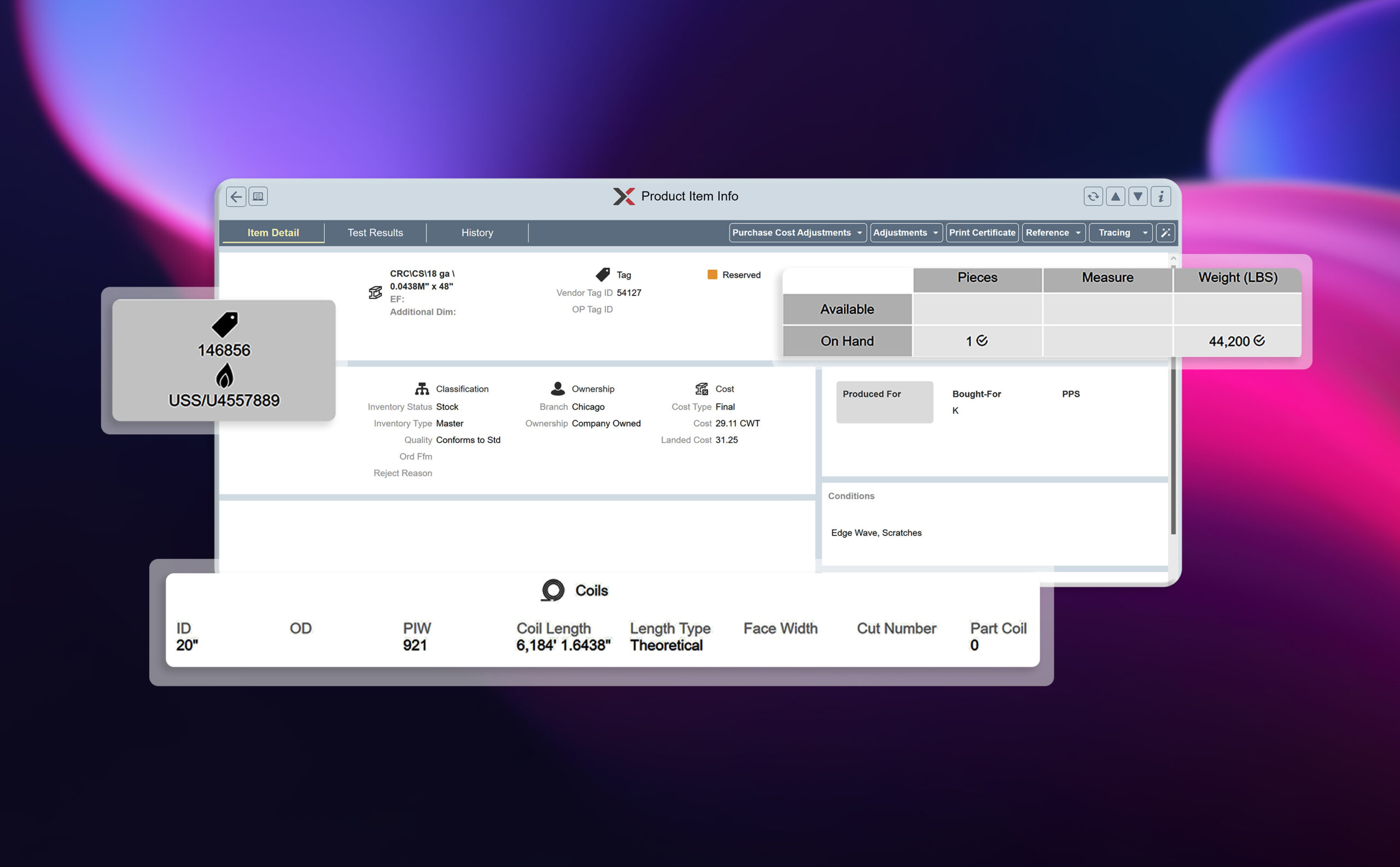

Metal at its core

All screens, fields, and lookups are built for the metal industry with a focus on ease of use and speed of entry.

Implement Fast. Implement INVEX.

INVEX facilitates digital transformation for the metal industry and ensures swift

implementation at steel service centers with minimal, if any, software modifications.

The Metal ERP + eCommerce Software Solution.

The INVEX metal software, combined with a ready-to-use eCommerce solution, provides a unique solution in the metal industry. As quotes and orders are submitted by customers through the eCommerce platform, these orders are then created, fulfilled, and invoiced by the metal ERP software. Customers can also browse inventory for items such as stainless angles or steel sheets before adding the items to an easy-to-use cart.