toll processing

INVEX software built for service centers focused on toll processing

INVEX offers comprehensive functionality for metal and steel toll processing companies that process customer owned inventory. Common business cases such as metal and steel coil slitting, decoilling and cut-to-length can be handled quickly and out-of-the-box. Steel and metal toll processing features, also known as steel toll conversion, are also available for metal companies that process customer owned material.

Toll processing companies, which are also referred to as metal and steel toll conversion or toll manufacturing, typically slit, cut-to-length, decoil and shear customer owned metal and steel coils and sheets. . Toll processing can also be performed on painted coil products and virtually any process such as shearing, rolling, galvanizing, pickling and cold rolling.

The INVEX Toll processing functionality can encompass all types of products and processes including bars, plate, pipe and tubes

Production includes specialized layout functions for metal and steel slitting, cut-to-length, multi-strand blanking, oscillating, and shearing.

Each layout uses a special shop floor production recording system with barcode scanning to improve accuracy and streamline the recording function.

CASES HANDLED:

- Receive inbound material while in-transit from the mill on a vessel, truck, or barge

- Receive owned or customer owned material

- Spot toll orders

- Contract orders for repetitive parts

- Sales can create the work order with the slitting or processing setup

- Single or multi-step multi-plant processing

- Outside processing for processes such as coating or coil painting

- Handles slitting, cut-to-length, decoilling, blanking, shearing, multi-strand blanking

- Single or multi-strand oscillate winding

- Non-Conformance function for complaints and claims

Toll processing orders can be entered to process customer owned inventory with the option to bill at the time of production or shipping.

Both spot or toll contract orders are available. Toll contract orders can be used when processing repetitive customer parts for a customer.

Faster and easier to implement EDI with EDIX. EDI is an Electronic Data Interchange ready platform for metal service centers that makes it faster and easier to implement EDI.

PLATFORM INDEPENDENT

INVEX provides multiple features for toll processors to perform

essential functions all in a platform independent software

- Coils are controlled by pieces, coil length, and weight

- Painted coils are be controlled by pieces, coil length, area, and weight

- Flexible stock search features to search for material owned by a particular customer

- Coil inventory can be received with the Customer and mill Tag number

- Full cycle inventory tag tracing (trace from parent to child)

FLEXIBLE STOCK SEARCH

- Search by spec (ASTM, ASME, etc.)

- Conditions, holds, and quality codes

- PIW and KCW ranges

- View substitute products

- Wild card grade and finish codes

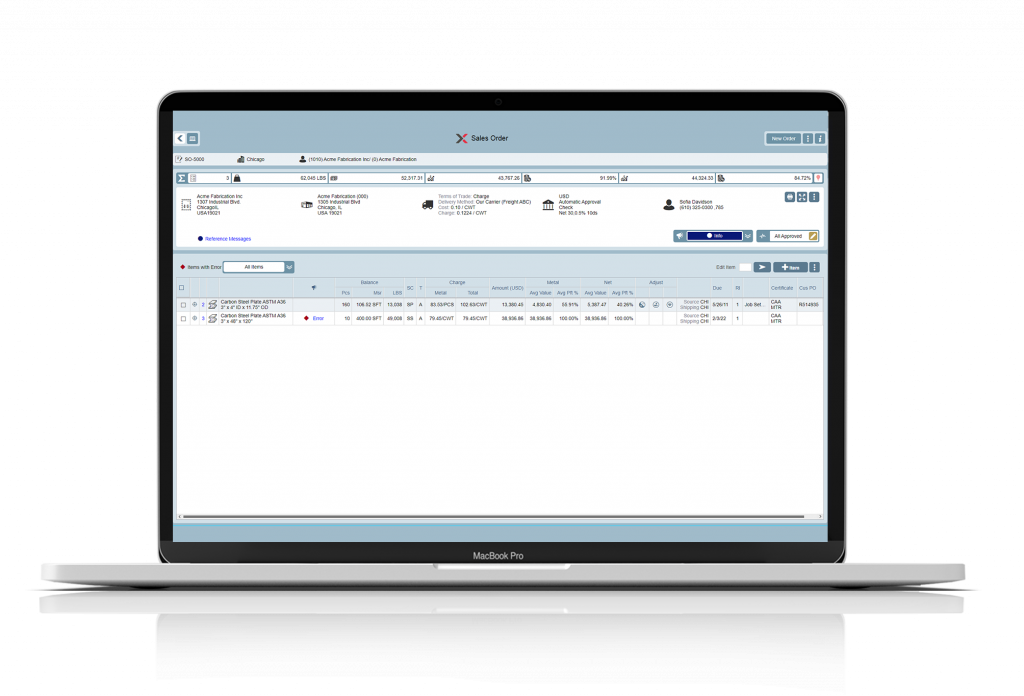

The sales order entry function has a streamlined order entry function which starts with the entry of the customer tag or consumed coil product.

- Setup of repetitive customer parts

- Sales can indicate if the toll material is produced to stock or for shipment

- Viewing finished good JIT inventory produced in advance to a customer part

- Sales can view a list of customer parts and view the finished goods that are ready for shipment

- Specify if sheet weight is based on actual, theoretical minimum, or nominal weight

- Email material receipt acknowledgement to customer

- Customer inventory statements

- Value add costing

- Multi-step processing (slit, cut-to-length/decoilling, shear)

- Online inquiry functions for planning, scheduling, and production recording

- Production Planning function to group multiple items onto the same Production Job

- Specialized layout functions for metal and steel slitting, cut-to-length, and shearing

- Handles single and multi-strand oscillate winding

- Handles multi-strand blanking that combines the attributes of slitting and cut-to-length

- Barcoded production labels for scanning at weigh stations

- Multiple banding and packaging modes using shop-floor Tablet functions

- Electronic scale integration

- Record actual thickness and dimension measurements for slit coil or sheet

- One of more slit coils can be ‘packaged’ onto a single tag

- Record actual coil length for slit coils based on the customer’s requirement

INVEX accommodates the following weighing options:

- Scale placed at end of packaging line

- Inline scale on banding line (with build-up)

- Re-coiler unload scale to weigh total output

- Stand-alone scale

toll processing invoicing

The invoicing function has a streamlined invoicing function specific to toll processing and the related processing charges.

- Streamlined order entry function

- Toll Orders

- Automated invoicing at the time of production or shipment

- Automated scrap credit options based on the customer and type of processing

- Option to invoice freight separately

- Ability to charge for skids when billing at time of production

- Customer inventory statements

- Option to invoice based on consumed (gross) or produced (net) weight by process

- Toll-specific reporting